Discover the New Features in Mastercam 2025

Mastercam 2025 is packed with new features and enhancements designed to streamline your workflow, boost efficiency, and maximize the potential of your machining operations. Here’s an overview of the standout updates and how they can benefit your programming and machining processes:

1. Workholding Updates

Mastercam 2025 introduces significant improvements to the way workholding is handled for mill and router machines. Users can now manage fixtures more effectively within the machine group setup. Fixtures can be grouped, turned on or off with a checkbox, and used across multiple operations seamlessly, enhancing both simulation and verification processes.

2. A-axis Contour Turning

The new A-axis Contour toolpath for B-axis mill-turn machines allows for more flexible and efficient turning operations. This toolpath enables the spindle to index to specific angles, allowing the tool to rotate and access features that were previously difficult to machine. This functionality enhances the tool’s ability to maintain optimal cutting conditions and achieve better finishes.

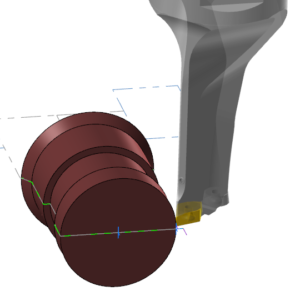

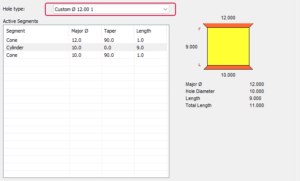

3. Solid Hole Selection

Mastercam 2025 simplifies the process of selecting and programming holes, even on “dumb” solids. The software can automatically read the hole geometry and recognize all segments, making it easier to program complex hole features without additional steps. This update enhances flexibility and efficiency in drilling operations.

4. Safety Zone Enhancements

Safety zone improvements in Mastercam 2025 provide greater control over multiaxis drilling motions. The software now calculates rectangular, cylindrical, and spherical shapes as meshes in the background, resulting in smoother and more precise tool movements. Additional fields for feed rates and linear tolerance settings further enhance the control and efficiency of multiaxis operations.

5. Visual Linking for Toolpaths

Visual linking parameters in Mastercam 2025 offer a clear visual representation of linking movements in 2D and 3D toolpaths. This feature provides a bird’s eye view of the toolpath, making it easier to understand and optimize tool movements for various features on the part.

6. Finishing Passes for Dynamic Mill

The addition of finishing passes within the dynamic mill toolpath allows users to perform both roughing and finishing in a single operation. This feature reduces programming time and enhances the efficiency of milling operations, ensuring precise wall finishes directly within the dynamic mill process.

7. 3-Axis Deburring

Mastercam 2025 introduces the 3-axis deburring toolpath, an add-on to the standard 3D milling license. This toolpath simplifies the deburring process by allowing users to apply deburring operations to complex parts using ball nose and lollipop tools, reducing the need for manual deburring and improving overall part quality.

8. Improved Associativity for Toolpaths Against Mesh Models

Machining against mesh models has become more efficient in Mastercam 2025. The software now maintains better associativity between mesh models and toolpaths, ensuring that any modifications to the mesh are automatically reflected in the toolpath. This enhancement simplifies the workflow for users working with mesh data.

9. Swarf Milling with the Tip of the Tool

Swarf milling toolpaths in Mastercam 2025 now support cutting with the tip of the tool. This capability expands the range of applications for swarf milling, allowing for more precise and efficient machining of complex geometries.

10. Machine Configurations for Mill-Turn

Mastercam 2025 allows users to save and load machine configurations for mill-turn machines. This feature saves time by allowing users to quickly apply their preferred machine setups, including chuck, jaw, and tooling information, across multiple jobs without needing to reconfigure each time.

Benefits of Mastercam 2025 Training

Investing in Mastercam 2025 training can significantly enhance the skills of your programmers and machinists. Training ensures:

- Efficiency: Master the new features and streamline your programming processes.

- Better Cycle Times: Optimize toolpaths and reduce machining time.

- Safety: Implement safer machining practices with improved toolpath control.

- Full Software Utilization: Unlock the full potential of Mastercam 2025’s capabilities.

We offer both online and in-person training options, including exclusive on-site training and significant discounts. Our training sessions are designed to help you fully utilize the latest features, making your programming and machining processes more efficient and effective.

Ready to take your Mastercam skills to the next level? Contact us to learn more about our training programs and how they can benefit your operations.

GET THE MOST OUT OF MASTERCAM 2025